How to connect and

trigger a

LED light source with a

machine vision camera from Daheng Imaging using an

industrial strobe controller. This is applicable to both USB3 and GigE machine vision cameras that have a trigger output. As additional hardware we have used a 12V powersupply, a Power LED and a

triggerable industrial strobe controller, the ACC-MV-LED-STROBECONTROLLER-V1.

We have recently renewed this article on the product page of the industrial strobe controler.

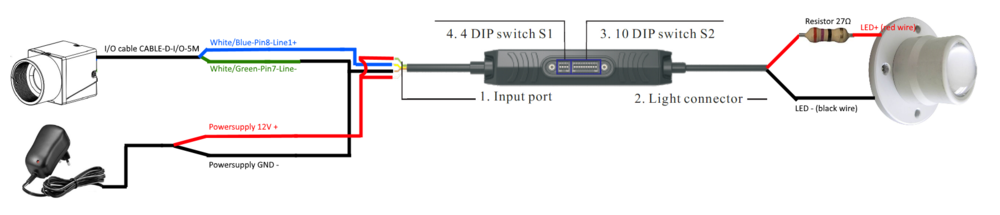

Step 1: Program the triggerable industrial strobe controller

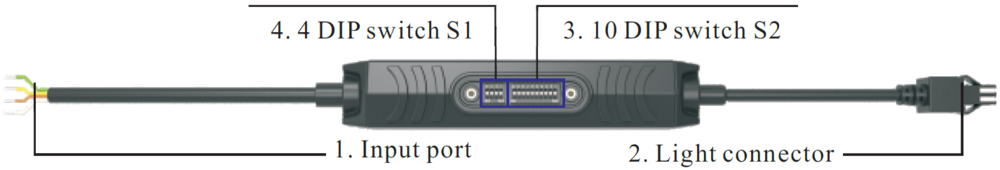

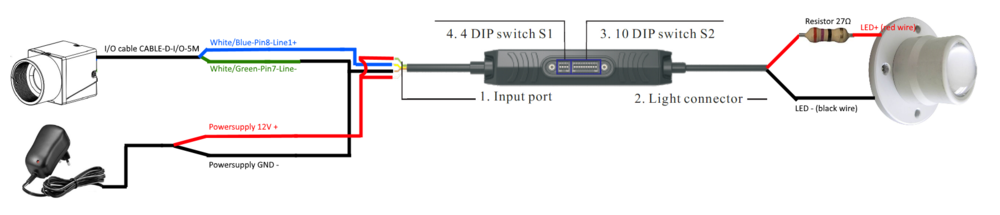

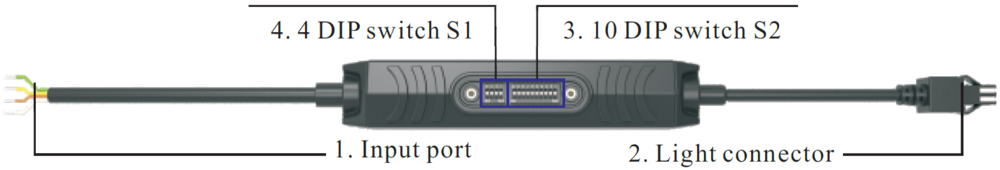

We are using in our example an

ACC-MV-LED-STROBECONTROLLER-V1 industrial strobe controller that can be triggered. A nice feature of this strobe controller is that you can program it, using the dipswitches, without the need of connecting the strobe controller to a pc. Most industrial strobe controllers can be triggered and have at least 4 inputs and 2 outputs, therefore this guide can be used for many industrial triggerable strobe controllers.

Inputs:

- White wire = Power+

- Brown wire = Power –

- Green wire = Trigger +

- Yellow wire = Trigger –

Output is a 2 pin connector. However when you remove the connector you will see:

- Red wire = LED+

- Black wire = LED-

The most easy setting is to program the DIP switch of the industrial strobe controller for trigger on rising edge. The position of the DIP switch S1 will be:

- In case of strobe pulse 10-1023us = Dipswitch 4,3,2,1 are ON-OFF-OFF-OFF, see image

- In case of strobe pulse 11-1023ms = dipswitch 4,3,2,1 are OFF-OFF-OFF-OFF

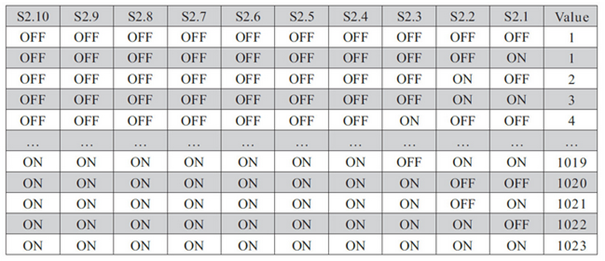

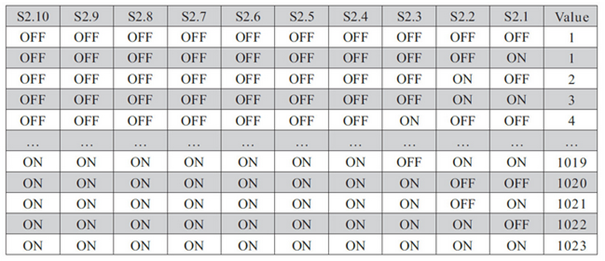

The position of DIP switch S2 of the strobe controller is for the length of the pulse:

In our example we want to have the smallest strobe time of 10us. Therefore the position of Dipswitch S2 are all OFF, see image below.

Step 2: Connect the LED to the industrial strobe controller

There are 2 options for the LED. Option 1 is to use a ready of the shelve industrial machine vision light that operates on 12V or 24V and consumes not more then 2A.Or you can connect your own LED light. In our case we have bought a

ledxon 9008246 high power LED that produces a very narrow but powerfull light bundle of 3 degree. It consumes 350mA at 2,8V. Because we want to connect a LED and not a standard industrial machine vision light, we have to add some resistors to make it work.

The calculation for the resistor is: (Powersupply voltage – LED Voltage ) / LED current

In our example the resistor value = (12V-2.8V)/0.350A=26Ohm. Because a 26Ohm resistor does not exist we take a 27Ohm resistor.

Need support? Contact us!

Step 3: Connect the industrial machine vision camera with the powersupply and strobe controller

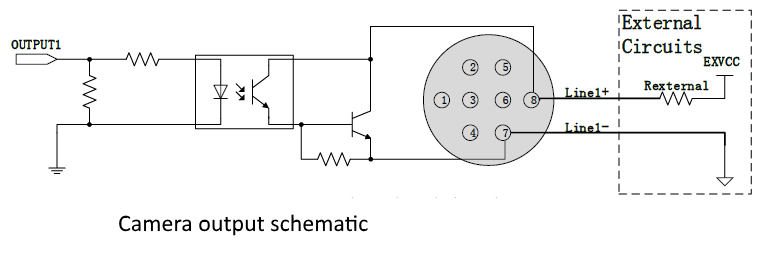

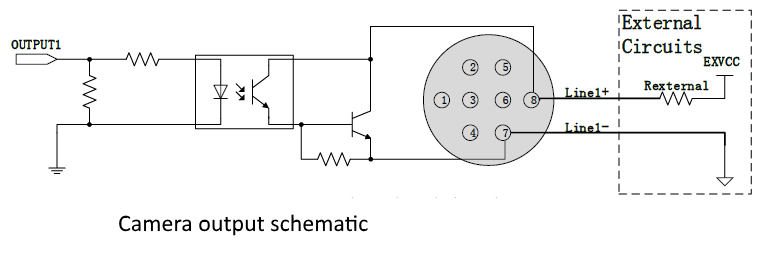

To connect an industrial machine vision camera you need to have an

I/O cable. In our case we are using a CABLE-D-I/O-5M. We need to use the (strobe) output of the industrial vision camera to trigger the strobe controller. In our case it’s an optocoupled output called line 1 using pin 7 (Line1- White/blue wire) and 8 (Line1+ White/Green wire) of the industrial vision camera

I/O connector.

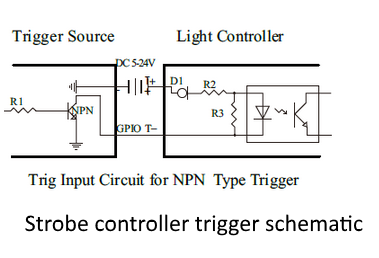

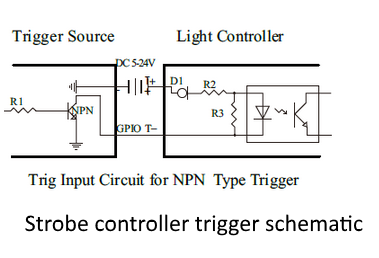

The

I/O cable of the industrial machine vision camera must be connected to the input port of the industrial strobe controller. The industrial strobe controller has the following schematic:

To make all connections complete we have made a simplified drawing with the correct colors on how to connect the industrial machine vision camera, with the industrial strobe controller and the powersupply.

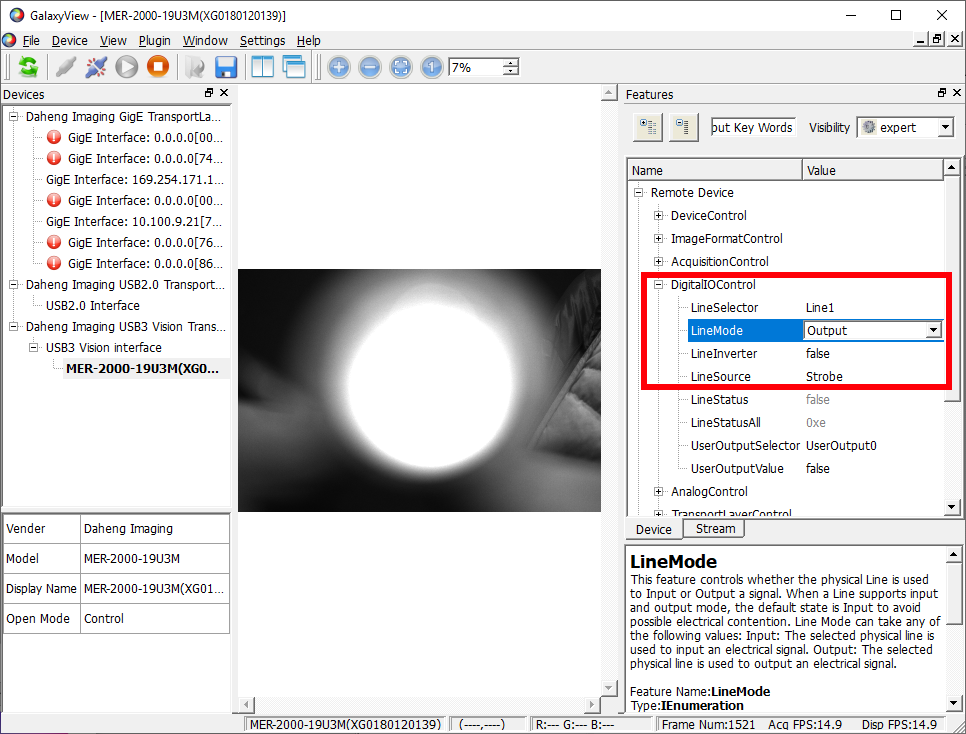

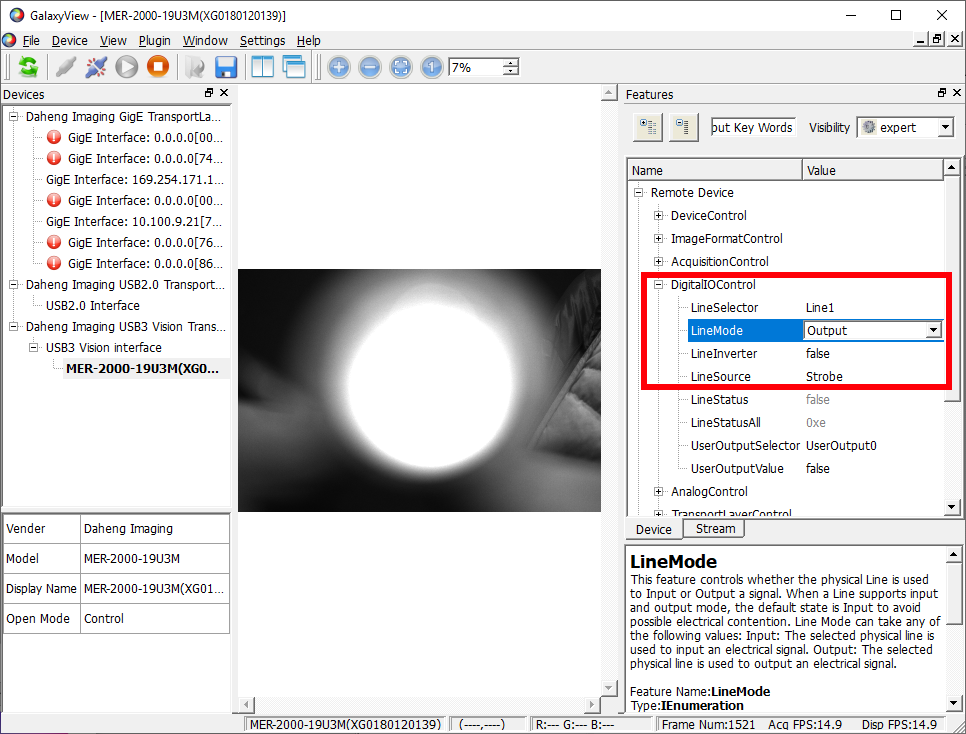

Step 4: Setup trigger and strobe settings of industrial machine vision camera

Connect the USB3 cable to the industrial machine vision camera and to the pc. Now start the

SDK software of the machine vision camera (GalaxyView application when using a Daheng Imaging Camera) and connect to the industrial machine vision camera. To make the triggering working, make sure that you set the following settings (marked in the red box):

Lineselector -> line1

Linesource -> strobe

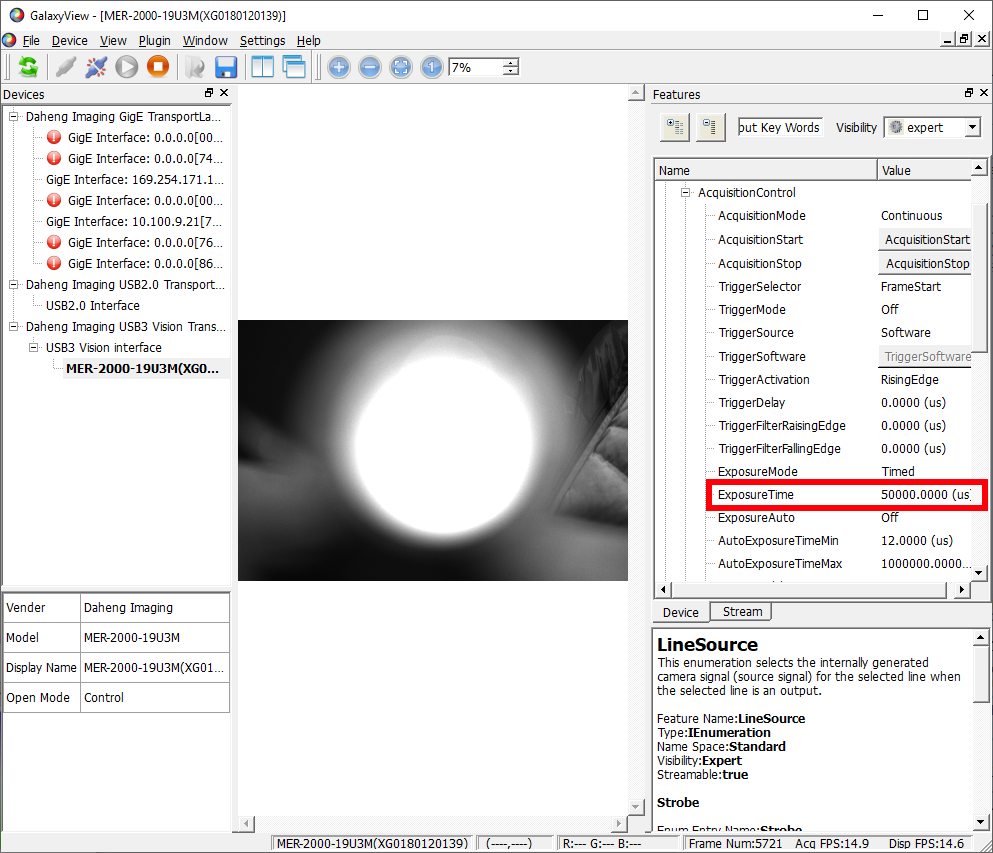

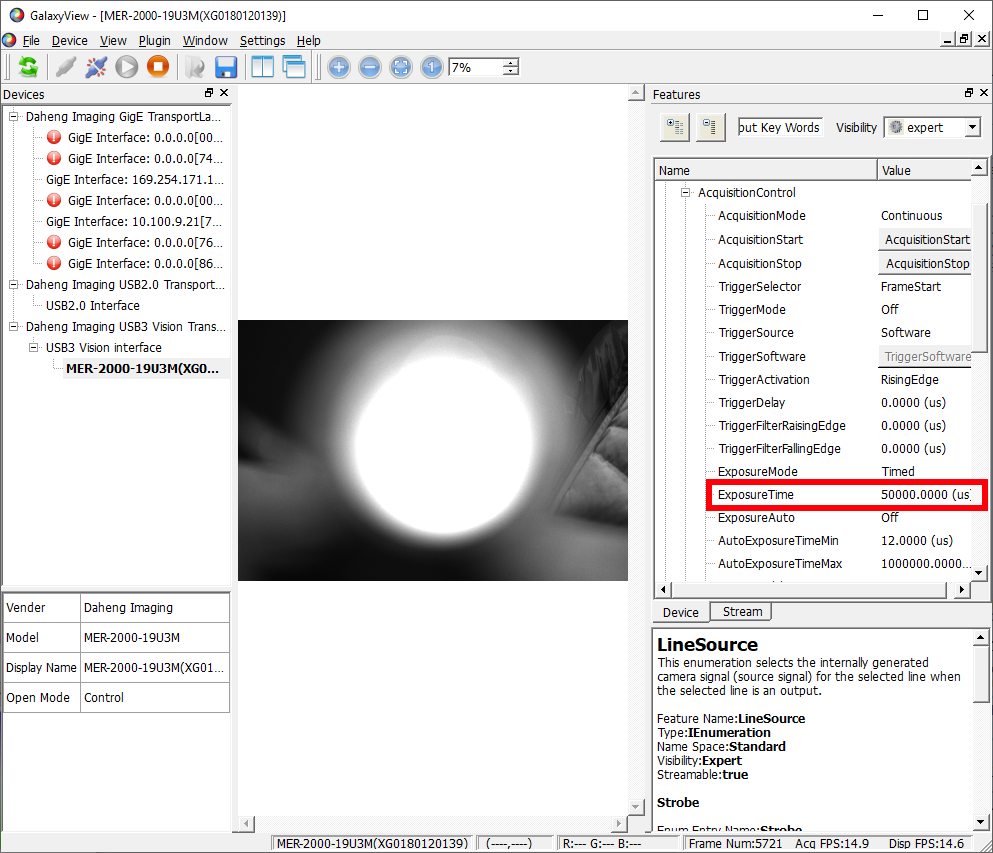

Step 5: Setup exposure time of industrial machine vision camera

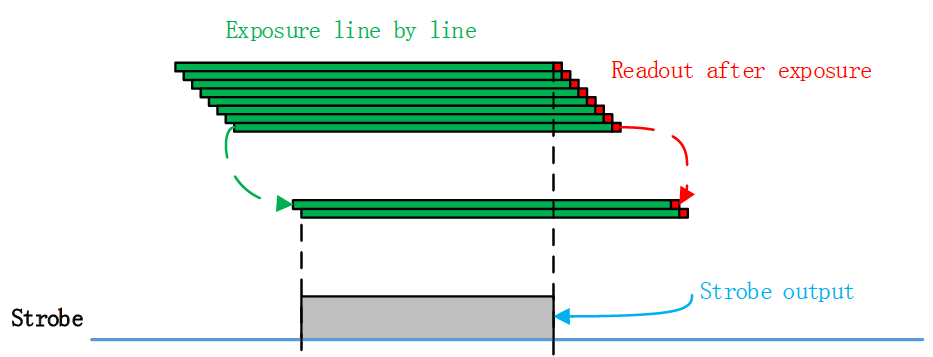

Now the triggering is programmed we have to set the exposure time. For a

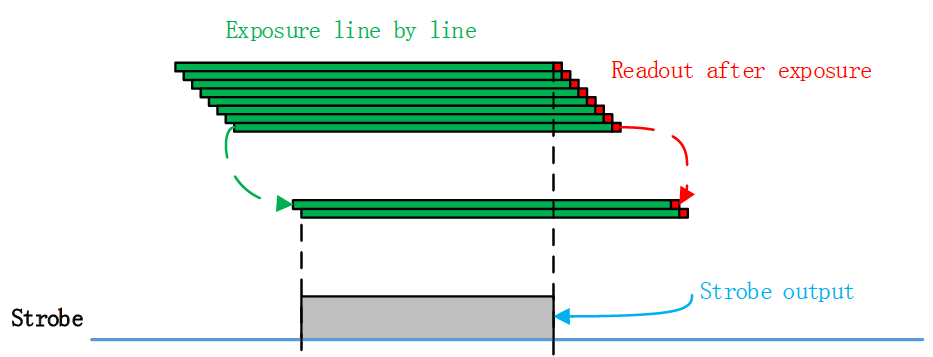

global-shutter industrial machine vision camera this is easy, because you can make it any value. For a

rolling-shutter machine vision camera this is not the case.

When a rolling shutter sensor is used, the strobe output will only work during the period that all lines of the sensor are exposed. In general you can say that the minimum exposure time, for using a strobe output = 1 / (max framerate). In our example the industrial vision camera can achieve 19fps, so minimum exposure time = 1/ 19 = 52ms. After 52ms all lines are exposed and you can flash. If you want to flash a LED for 1ms (Strobe output time) the calculation for the exposure time = minimum exposure time + Strobe output time) = 52ms + 1ms = 53ms. You will notice that when you reduce for example the exposure time to 10ms, the strobe output is not working anymore.

Using an exposure time of 53ms, could mean that the industrial vision camera is also capturing light from the environment. To solve that, you have to close the iris of the lens further. To do this:

- cover up the LED.

- Then close the iris of the lens till you see a black image.

- Now uncover the LED

- Adapt the brightness of the image by closing the Iris further (when the image is over illuminated) or increase the strobe output time (when image is to dark).

In the software of the industrial machine vision camera you can set the exposure time under AcquisitionControl->ExposureTime

Now you have a working setup, where the

industrial machine vision camera, triggers the industrial strobe controller to flash a LED.