This article explores the basics of polarization and how it can be applied in diverse machine vision applications. Additionally, it places focus on cross-polarization; an advanced technique that enhances image quality by minimizing glare and revealing hidden details. Are you currently working on an application involving surface inspection, experiencing issues with glare or needing some advice on a similar application? We can assist with the selection of the right polarization hardware.

What exactly is polarization in machine vision?

Polarization aligns the orientation of light waves towards a specific direction. It offers machine vision systems a unique tool that can extract information from a scene that is invisible when using conventional imaging methods. Polarization-based techniques add a new layer of contrast and detail, making them invaluable to a variety of industrial, scientific, and medical applications.

External light sources, such as the sun or LED lights, emit light waves with random orientations of their electrical fields. This is known as unpolarized light because the oscillations occur in all possible directions perpendicular to the direction of propagation. When unpolarized light passes through certain materials or filters, it can become polarized. For example, a polarizing filter allows only light waves oscillating in a specific plane (aligned with the filter's polarization axis) to pass through, while blocking light oscillating in other planes.

When light reflects off a surface, it can become partially polarized. At certain angles, the reflected light is polarized parallel to the surface. These properties of light can be used in machine vision to make features visible and improve results.

• Surface Inspection: Polarization highlights surface defects, scratches, and imperfections that might go unnoticed under normal illumination.

• Glare Reduction: Polarization can mitigate glare and reflections from shiny surfaces, enhancing image quality.

Which polarization solution can I use for my machine vision application?

When using polarization in machine vision to eliminate glare, it is important that all external light source and the lens have a polarized filter.

When you would like to minimize reflections from external light sources,

our linear polarizing filter sheet offers a great solution. This filter sheet can be cut to size and placed in front of the machine vision light source. This polarizing filter sheet is often used in combination with

bar lights.

For the lens you can make use of the linear polarizing filter, available in a variety of sizes. For example:

Polarizing filter | Linear | M30.5 (get-cameras.com). The filter can be twisted to change the direction of polarization so that adjustments for optimal results can be made. We offer a broad portfolio of polarizing lens filters, most of which are active between 400 and 780nm.

Do you need help selecting the right set-up? Read further for more information or please contact us below.

Cross-polarization to improve your machine vision setup

Cross-polarization is an advanced polarization technique that involves using a pair of polarizers oriented at right angles to each other. This arrangement allows only the light with a polarization perpendicular to the second polarizer to pass through, effectively blocking glare and specular reflections. Cross-polarization is employed to:

• Minimize Glare: By eliminating reflections, cross-polarization enhances contrast, revealing fine details and imperfections.

• Surface Inspection: The technique exposes hidden features and defects that specular reflections might obscure.

Which cross-polarization solution do I need?

In our test setup we made use of polarizing filters in front of an existing machine vision light and the lens. An off the shelf solution is our

Industrial polarized ring light bright field (get-cameras.com). The light comes with two linear polarizing filters pre-installed. So there is no need to figure out a way to install the filter to the light.

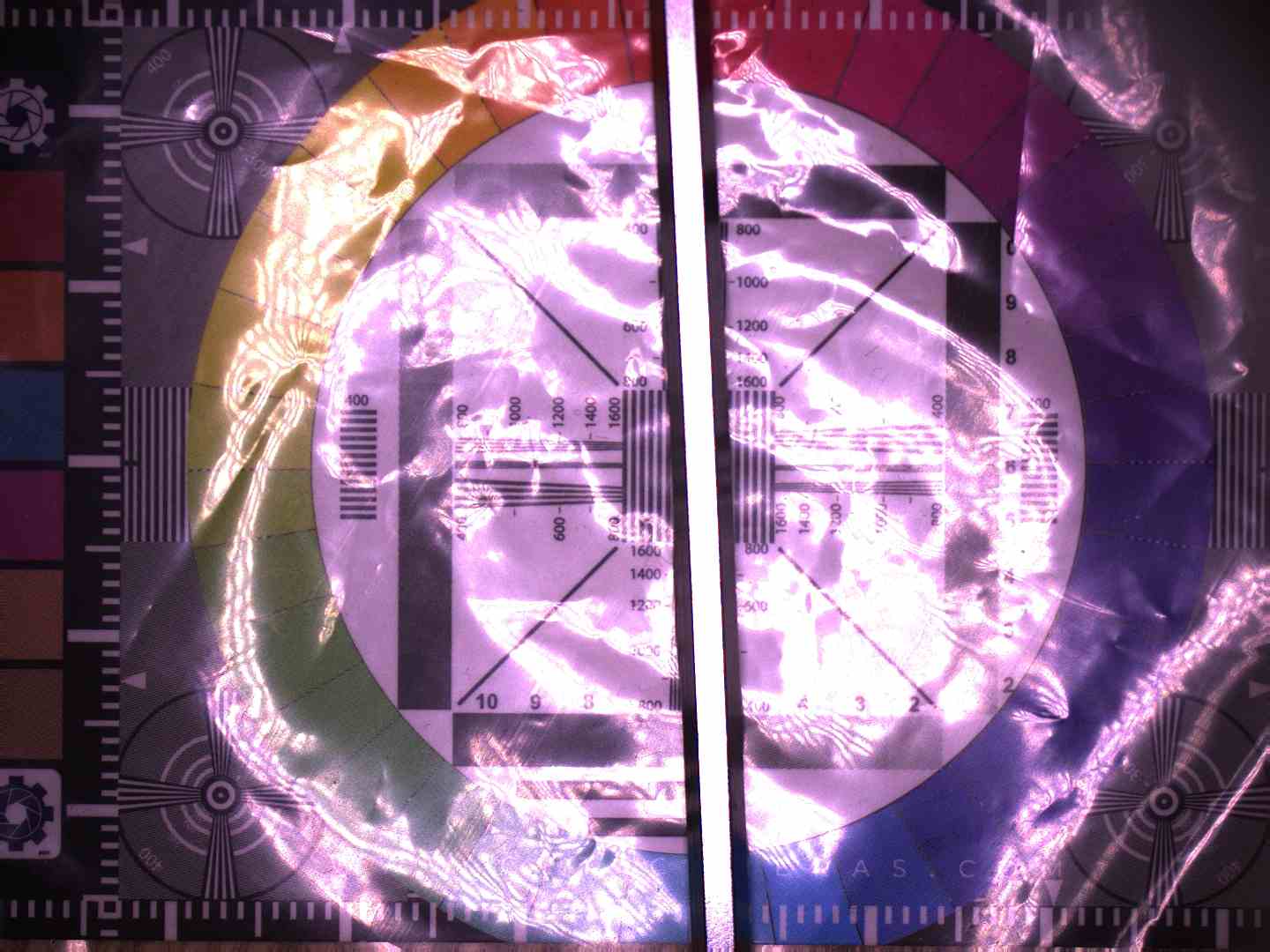

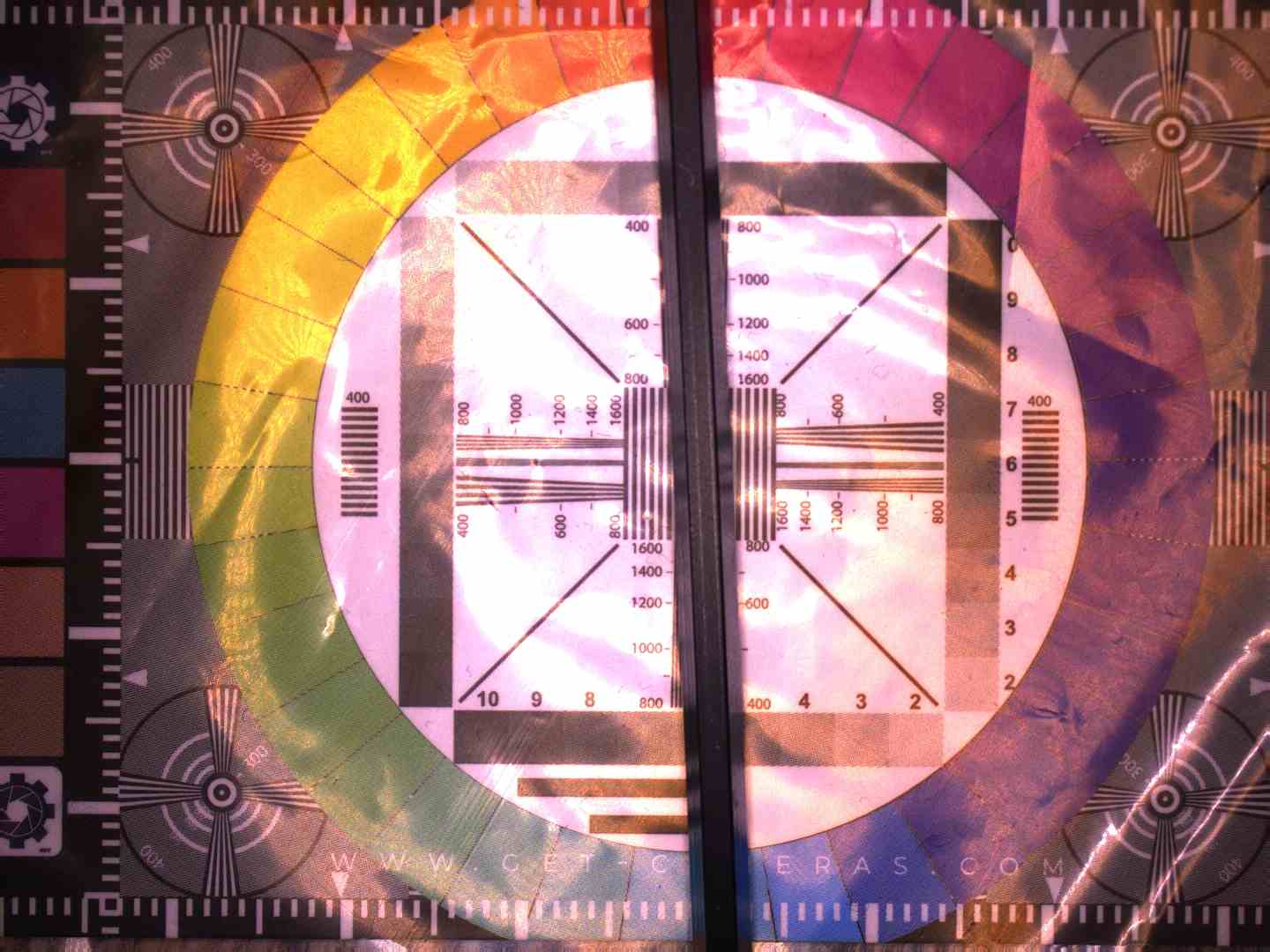

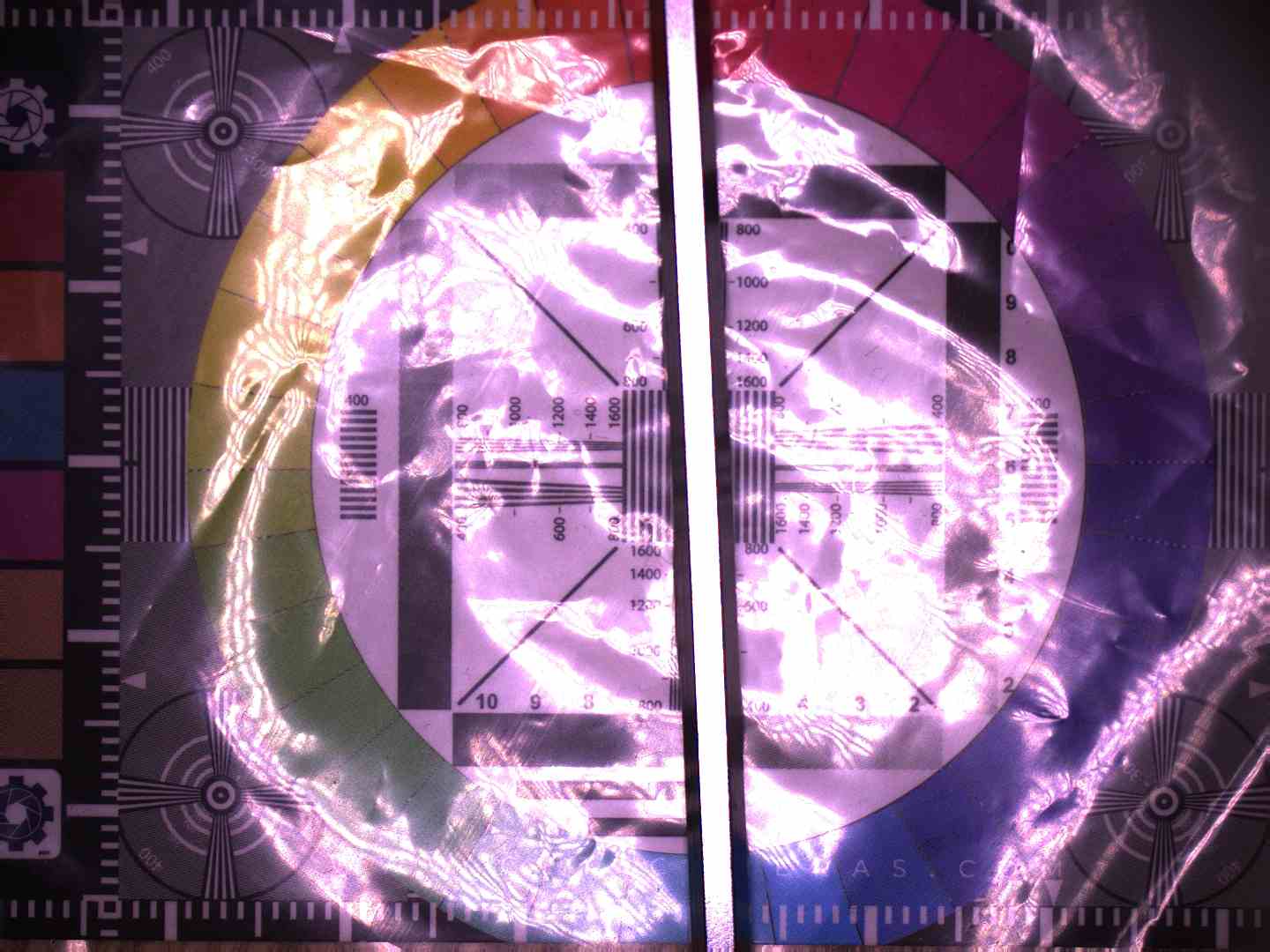

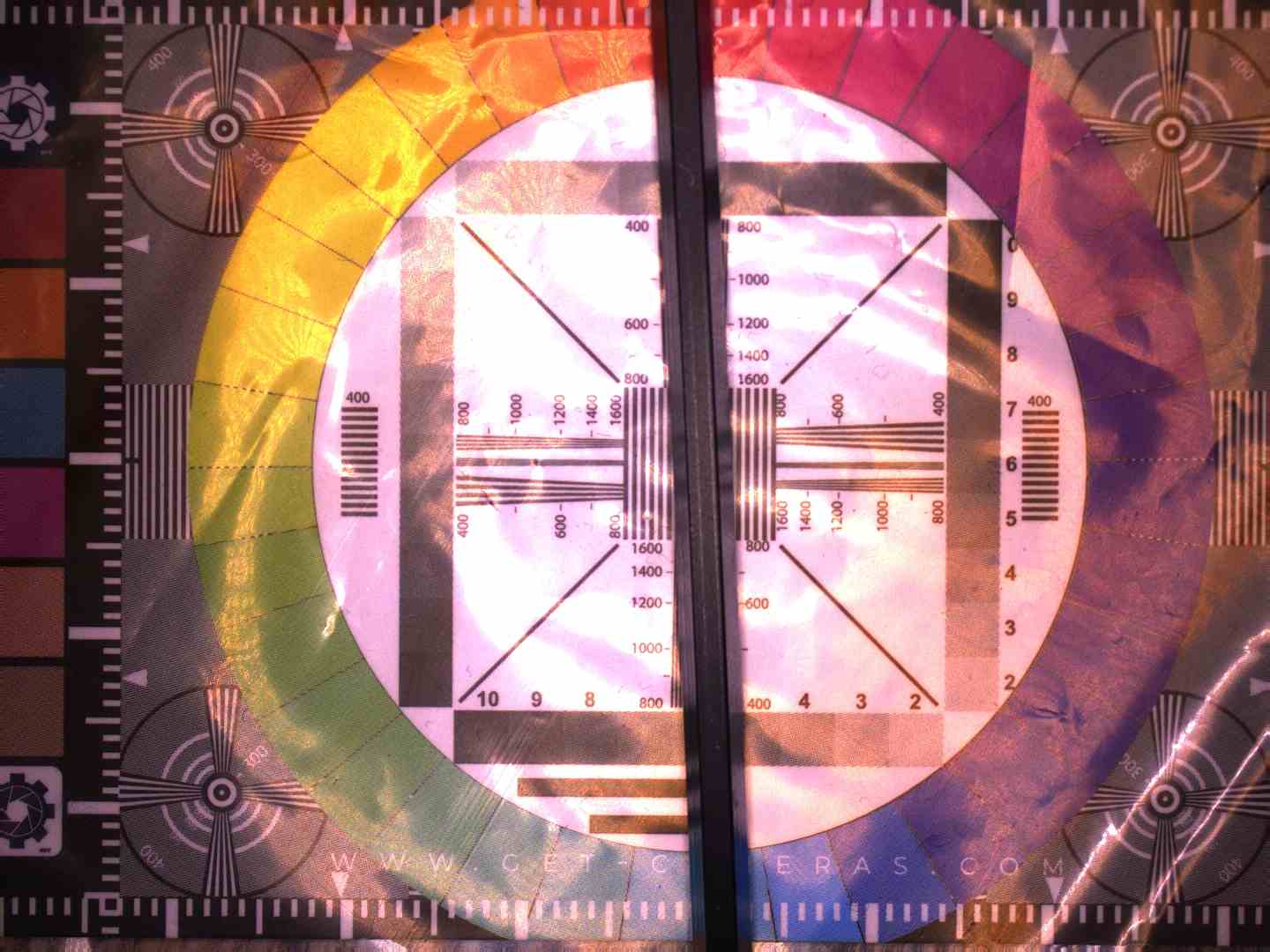

When comparing the images, notice the difference in the the visablitly of the reference card and the reflection on the surface of the allen key. Notice how there is no visable detail in the image on the left compared to the image on the right which has the perpendicular polarizing filter. Also notice the clarity of the allen key.

Our testing revealed that the industrial polarized ring light had a tenfold reduction of light intensity when illuminating a reflecting item. The exposure time for the left image was 1ms, while the exposure time for the image on the right was 10ms. Due to this loss of light intensity we increased the exposure time to compensate.

Similarly when testing on a diffuse object the light loss was slightly lower. In this case when using a polarized light we had to increase the light intensity by 6-10 times more compared to achieve the same light intensity when using non-polarized light.

Machine vision cameras with build-in polarizing features

In machine vision, polarization imaging involves capturing and analysing the polarization state of light reflected or transmitted by objects. This can provide insights into the properties of the material, surface characteristics, and more.

The following are key applications of polarization machine vision cameras:

• Material Differentiation: Different materials exhibit distinct polarization properties, enabling discrimination between similar-looking substances.

• Surface Inspection: Polarization highlights surface defects, scratches, and imperfections that might go unnoticed under normal illumination.

An introduction on this can be found in one of our other Knowledge Center articles:

Polarization camera whitepaper explains how polarization filters work (get-cameras.com).

Conclusion

Polarization imaging in machine vision expands the capabilities of traditional imaging methods, enabling the detection of features and details that might otherwise remain hidden. Cross-polarization, in particular, offers a powerful tool for enhancing image quality, reducing glare, and revealing critical information in various applications.